Deciding how to find a manufacturer for your product comes down to one big question: do you make it here or overseas?

This choice is the bedrock of your supply chain. It shapes your product's cost, its quality, how fast it reaches your customers, and frankly, how much you'll worry about it.

Choosing Your Manufacturing Path

Think of this like hiring someone to build a deck. You can hire a local crew you can watch every day. Or you can hire a team across the world that might save you money but adds layers of complexity. Neither is wrong, but one is right for you.

There's no single "correct" answer. The only right answer is the one that fits your product, budget, and comfort level with risk.

Be honest with yourself. What matters most? Is it the lowest possible unit cost? Or is it launching a new color in six weeks instead of six months? Does your product need such precise quality that you must be there in person?

The difference between a factory in your state and one in another country is more than just price. It's a different world of communication, shipping, quality control, and even how customers see your brand.

Domestic vs. Overseas at a Glance

Let's break down the major trade-offs. This isn't everything, but it covers the big picture.

| Factor | Domestic Manufacturing | Overseas Manufacturing |

|---|---|---|

| Unit Cost | Generally higher | Generally lower |

| Lead Time | Shorter (weeks) | Longer (months) |

| Shipping | Faster, cheaper, simpler | Slower, more expensive, complex |

| Quality Control | Easier; you can visit | Harder; needs a third party |

| Communication | Same time zone, language | Time differences, language hurdles |

| IP Protection | Stronger legal shield | Higher risk of theft |

| Minimum Order | Often lower | Often much higher |

| Payment Terms | More flexible (Net 30/60) | Less flexible (50% upfront) |

This table shows that "cheaper" overseas often has hidden costs in time and risk. "Expensive" domestic manufacturing buys you speed and control.

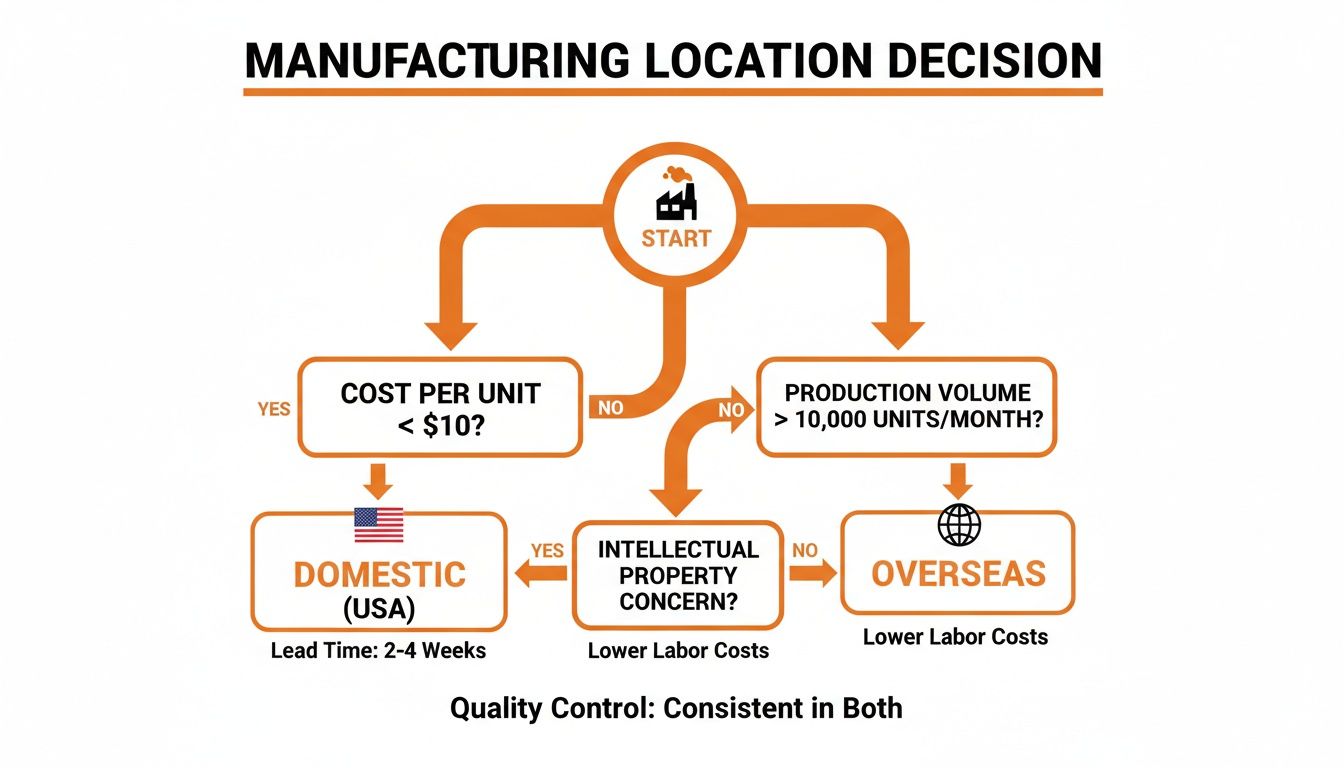

This flowchart helps visualize how your priorities point you one way or the other.

As you can see, how much you're making and how unique your product is are the major forks in the road.

Why Make It Here?

Working with a domestic manufacturer has huge, real advantages. It’s more than a "Made in the USA" sticker.

Lead times can shrink from three agonizing months to four manageable weeks. Shipping is a breeze—no container ships, customs brokers, or surprise tariffs.

Most importantly, you can be there. You can drive to the factory, hold the product, and talk directly to the person in charge. For a complex product or for founders who need that hands-on control, this is priceless. If you're just getting started, our guide on how to start a product business can help you think through these early stages.

Domestic manufacturing often means higher unit costs, but it buys you speed, control, and peace of mind. It’s the right move for brands that live and die by quality.

Why Make It Overseas?

Let's be real: the number one reason to go overseas is cost. The dramatically lower labor costs in countries like China or Vietnam are a powerful magnet.

That cost difference can mean better profit margins or a more competitive price. Factories abroad are also built for massive scale, able to produce volumes that would overwhelm most smaller US shops.

But this path isn’t for the faint of heart. You'll deal with different languages, business cultures, and a 12-hour time difference. Shipping is its own world of freight forwarders, customs holds, and port delays that can leave your inventory stranded for weeks. It demands rock-solid systems and crystal-clear communication.

Finding Your Manufacturing Partners

Okay, you've chosen a direction. Now, the real work begins: building a shortlist of potential factories.

Think of yourself as a scout for a sports team. You don't just pick the first person who looks good. You build a deep list of 10-20 potential partners to put through their paces. This is how you find a champion for your product.

But where do you actually find these factories? The best partners come from a mix of smart online searching and good old-fashioned human connection.

Mastering Online Marketplaces

The easiest place to start is with large online supplier directories. Think of these like different fishing spots. Some are massive lakes where you can catch anything. Others are small streams known for a specific type of fish.

- [Alibaba] & AliExpress: These are the giants, mostly for sourcing from Asia. Alibaba is for bulk orders and custom manufacturing. AliExpress is better for smaller quantities or testing an existing product.

- [ThomasNet] & Maker's Row: These are gold mines for US manufacturing. They help you find specialized American factories, from a metal fabricator in the Midwest to a textile mill on the East Coast.

- [MFG.com] & Kompass: These sites are great for industrial or technical products. They connect you with partners who have specific engineering skills all over the globe.

When digging through these sites, use the filters. On Alibaba, look for suppliers who are "Verified" or have "Trade Assurance." This is your first line of defense. It shows a third party has confirmed they're a real business, which cuts down your risk.

That "Verified Supplier" badge isn't just a shiny icon. It means someone has walked the factory floor and confirmed it’s real. Never skip this filter.

Beyond the Screen: Where the Real Gems Are

Online directories are a great start, but they are only half the story. The best manufacturing leads often come from real-world connections. You have to get out from behind your computer.

Think about it: anyone can create an online profile. It takes commitment to show up in person. The manufacturers you meet at a trade show or through a friend are often the most reliable players.

Your Factory Hunting Plan

Here’s a practical breakdown of the best places to find your ideal factory.

-

Industry Trade Shows

This is where the magic happens. A single day at the right trade show is more valuable than weeks of online searching. You can talk directly to factory reps, hold their samples, and get a true feel for their work. -

Professional Networks and Referrals

Tap into your network. Ask other entrepreneurs who they use. A referral from a trusted source is gold because it comes with built-in vetting. It lets you skip the line. -

NAICS Code Searches

This is a secret weapon. The North American Industry Classification System (NAICS) gives every industry a code. Searching for your product's NAICS code plus "manufacturer" (e.g., "NAICS 315220 manufacturer") will uncover qualified factories that general Google searches often miss. -

Sourcing Agents

If going overseas feels overwhelming, a sourcing agent can be your guide. They have existing relationships with factories and help with communication, negotiation, and quality control for a commission. They can save you from a world of headaches.

By blending these strategies, you’re not just making a list. You're building a curated portfolio of potential partners. This ensures you aren't putting all your eggs in one basket. For more on these steps, check out our guide on how to start an ecommerce business.

Vetting Factories to Avoid Costly Mistakes

So you have a list of potential suppliers. That’s just the starting line. Now comes the hard part: figuring out who you can trust to build your product. Vetting a manufacturer is like hiring a key employee—you have to go way beyond their resume.

Your manufacturer isn't just a vendor. They're your partner in creation. A bad partner can sink your business with delays and poor quality. A great one becomes a massive competitive advantage.

First Impressions Matter

How a factory replies to your first email tells you almost everything. Are they prompt and professional, or do you get a one-line reply three days later? That first interaction sets the tone.

Your first message should be short and direct. Introduce yourself, briefly describe your product, and ask a few simple questions. You're not negotiating yet; you're just seeing who’s serious.

Pro Tip: A huge red flag is a factory that says they can make anything. True experts specialize. Vague claims usually mean you're talking to a middleman, not a specialist.

The Must-Ask Questions

Once you’ve made contact, it’s time to dig in. Your goal is to understand their experience and process. Ask direct questions and expect clear answers.

Here are the non-negotiables:

- Experience with Similar Products: Ask for examples of products they've made that are similar to yours. Check the material, complexity, and quality.

- Key Certifications: Request copies of their quality certifications, like ISO 9001. This proves they have documented processes for quality.

- Subcontracting: Do they handle all production in-house? You need to know exactly who is touching your product.

- Defect Policy: What happens when things go wrong? And they will. Clarify their policy for handling defective units before you sign anything.

A great factory welcomes these questions. A sketchy one gets defensive. Trust your gut.

Verifying They Are Real

Sadly, scams exist. Verifying that a partner is a legitimate business is a step you cannot skip.

For overseas suppliers, ask for their business license and use a third-party service to confirm it's valid. For domestic manufacturers, checking with the Better Business Bureau (BBB) is a smart move.

This isn't paranoia; it's professionalism. You're protecting your investment. For more firsthand stories, check out these posts on local manufacturing and sourcing.

The Power of a Tour

Seeing is believing. Nothing replaces a factory tour, whether in person or over a live video call. It's your chance to see their operation with your own eyes.

During the tour, look beyond the shiny machines. Pay attention to the details:

- Cleanliness: Is the factory floor tidy or a mess? A clean space often means a disciplined process.

- Worker Conditions: Do employees seem engaged and safe? A factory that treats its people well is more likely to treat your product with care.

- Quality Control Stations: Look for dedicated areas where products are actively being inspected. This shows quality is built into their workflow.

A factory's refusal to give you a tour—even a virtual one—is an immediate deal-breaker. A transparent partner has nothing to hide. This vetting process protects you from expensive mistakes.

From Prototype to Final Handshake

The leap from a design file to a physical product is where the magic happens. It’s also where a tiny mistake can become a huge headache.

Think of it like baking a complex cake for the first time. You wouldn't just guess the ingredients. You'd follow the recipe exactly and taste-test along the way. Prototyping and sampling are your taste tests.

The Tech Pack: Your Product's Blueprint

Before any work starts, your factory needs clear instructions. This is your tech pack. It is the single most important document you will create. It's the blueprint for your product, leaving zero room for guesswork.

A good tech pack is radically clear. It should tell the manufacturer everything they need to know without them ever having to ask a question.

What goes into a rock-solid tech pack?

- Detailed Schematics: Technical drawings with precise measurements for every component.

- Bill of Materials (BOM): A complete list of every single raw material, down to the exact screw or thread color.

- Color Codes: Don't just say "blue." Use a universal system like Pantone to ensure your navy doesn't become baby blue.

- Reference Images: Photos and renderings from every angle, highlighting key features.

Without a detailed tech pack, you are inviting expensive mistakes. "Use a strong fabric" is worthless. "16 oz. 100% organic cotton canvas, color Pantone 19-4052 TCX" is an instruction they can execute perfectly.

The Two Samples You Must Get

Once the tech pack is done, get physical samples. It's tempting to rush this, but you must see and feel the product before committing to a full order. You need two types of samples.

- The Prototype: This is the very first version. Its only job is to test form and function. It proves the design works.

- The Production Sample: This sample is made with the final materials on the actual production line. This is what your customers will receive.

Do not skip the production sample. It is your last chance to catch issues before you’ve paid for thousands of units.

Key takeaway: Approving the production sample is your point of no return. Once you sign off, you agree that any unit matching that sample is acceptable. Keep one for your records as a "control sample" to compare against the final shipment.

Nailing the Deal

With an approved sample, you’re ready to talk numbers. A great negotiation isn’t about squeezing your partner. It’s about building a fair deal that works for both of you.

Your goal is a win-win partnership. A manufacturer who feels squeezed on price will find ways to cut corners. Focus on these three areas.

Finding Your MOQ Sweet Spot

The Minimum Order Quantity (MOQ) is the smallest order a factory will produce. For a new brand, a high MOQ can kill your cash flow. But MOQs are often a conversation, not a command.

If a factory's MOQ is 1,000 units but you can only manage 500, don't walk away. Explain your situation. Often, you can negotiate a lower MOQ on your first order if you pay a slightly higher unit price.

Structuring Fair Payment Terms

Here’s a rule to live by: Never pay 100% upfront. A reputable manufacturer won't ask for this. A standard deal is 50% upfront and 50% upon completion. This splits the risk and keeps both sides motivated.

Setting Realistic Timelines

Get a firm production timeline in writing. Ask for a breakdown: how long for material sourcing? For production? For packing? This schedule helps you manage your launch and holds them accountable. This handshake on the details builds the foundation for a long, profitable partnership.

A Deep Dive into Manufacturing in China

When you look for a manufacturer, many roads lead to China. It’s a massive manufacturing ecosystem. To think of it as just "the cheap option" is a huge mistake.

It’s better to see it as a sprawling city of specialists. One district excels at electronics, another is the go-to for textiles. Your job is to find the right neighborhood—and the right artisan—for your product.

Navigating the World's Factory

Let's talk numbers. China holds 27.7% of worldwide manufacturing output. Platforms like Alibaba list over 40 million suppliers. It's no surprise that 80% of US importers source from China. You can dig into more stats about the global manufacturing sentiment on blogs.opentext.com.

The sheer scale means you can find a factory for almost anything. But it also means you need a smart approach to cut through the noise.

The Alibaba dashboard is your gateway. The real work starts when you use filters like "Verified Supplier" and "Trade Assurance." These are your first line of defense against sketchy operators.

Your China Sourcing Playbook

Getting it right with Chinese manufacturers comes down to a few core rules. Think of these as your non-negotiables.

-

Communicate with Extreme Clarity: The language barrier is real. Use simple, direct English. Better yet, use visuals. Send detailed drawings, annotated photos, and short videos to explain what you want. Apps like WeChat are great for quick, direct chats.

-

Always Get Multiple Samples: I'll say it again: never commit to production based on one sample. It’s a rookie move. Shortlist your top three to five factories and get a sample from each. This is the only way to compare quality side-by-side.

-

Don't Let High MOQs Scare You: Many factories are more flexible than their listed MOQs suggest. If their page says 1,000 units but you can only start with 300, make an offer. You’d be surprised how often they’ll agree to a smaller first run.

A common mistake is accepting the first quote and MOQ as final. Treat it as an opening offer. A good factory wants a long-term partner, not a quick sale. They will often work with you.

The Non-Negotiable Final Check

If you remember only one thing, make it this: hire a third-party inspection service.

This is critical. Before your final payment goes out, you need an independent inspector to go to the factory and check your products. They pull random units and compare them against your approved sample.

This service is surprisingly affordable—usually a few hundred dollars—and it is the best insurance you can buy. They are your eyes on the ground. Skipping this step is a gamble you cannot afford to take.

The Case for US Domestic Manufacturing

While going overseas seems like the default, there's a powerful case for making your product right here in the US. Choosing a domestic partner is a strategic decision rooted in speed, quality, and protecting your ideas.

Think of it this way: managing an overseas factory is like a long-distance relationship. Communication is a hassle, and shipping takes forever. Working with a local manufacturer is like dating someone in your city. You can meet for coffee to solve a problem and get things done today.

Speed and Agility Are Your Secret Weapons

This is the biggest win for domestic manufacturing: speed. A production run that takes months to arrive on a ship from Asia can often be done and delivered in weeks from a US factory.

This speed is a real competitive edge.

- Launch Faster: Bring new products to market without the long wait.

- Cut Inventory Costs: No need to tie up cash in months of inventory.

- Pivot Quickly: Respond to market trends or restock a bestseller with incredible speed.

Better Quality Control and IP Protection

Nothing beats being able to walk your own factory floor. When your partner is a drive away, you can personally oversee production and solve issues in real-time. That hands-on control is impossible when your factory is thousands of miles away.

Plus, US manufacturers operate under strong intellectual property laws. The risk of your design getting copied is much lower. That peace of mind is priceless.

Choosing a domestic manufacturer is an investment in a resilient supply chain. You might pay a higher unit cost, but you get lower shipping fees, less risk, and the ability to pivot quickly.

The numbers don't lie. The US manufacturing output recently hit $2.91 trillion. You can tap into this powerhouse through platforms like ThomasNet or MFG.com, which list over 500,000 suppliers.

Sure, unit costs can be 25-40% higher, but domestic production can slash lead times in half. You can dive deeper into these global manufacturing trends on Safeguard Global.

The Big Questions: MOQs, Samples, and Lawyers

When you're new to this, a few questions always come up. Let's tackle the ones that trip up most people.

How Much Should I Expect to Pay for Samples?

It varies. Think of it like a test drive. A simple sample might be $50, but a complex one needing custom molds could easily pass $500.

I suggest budgeting $500 to $2,000 for the entire sampling phase. Why so much? Because you'll rarely get it perfect on the first try. You’ll go through a few versions, and that buffer saves you from stress and surprise costs.

What Is a Realistic Minimum Order Quantity?

A "good" Minimum Order Quantity (MOQ) depends on your product. A simple item from a huge factory might have an MOQ of 500-1,000 units. Don't let that number scare you.

Many suppliers, especially on platforms like Alibaba, are flexible. It's not uncommon to find MOQs as low as 50-100 units. The goal is to find a number you can afford that still lets you make a profit.

Your first MOQ is a negotiation, not a command. Many factories will agree to a smaller test run to build a long-term relationship. Don’t be afraid to ask for what you need.

Do I Really Need a Lawyer for My Manufacturing Agreement?

Yes. It's tempting to use a template, but hiring a lawyer with manufacturing experience is one of the smartest investments you can make. This agreement is your safety net.

It protects your intellectual property (IP), defines your quality standards, and locks in payment terms. The legal fee upfront is nothing compared to the money you could lose from a weak agreement when a deal goes wrong.

At Chicago Brandstarters, we believe that kind, bold founders deserve a community that has their back. If you're building a brand and value honest support over transactional networking, we’d love to connect. Learn more about joining our free community at https://www.chicagobrandstarters.com.

Leave a Reply